RDO Equipment Co. Founded in 1968, RDO Equipment Co. sells and supports agriculture, construction, environmental, irrigation, positioning, and surveying equipment from leading manufacturers, including John Deere, Vermeer, and Topcon. RDO Equipment Co. is a total solutions provider with more than 75 locations across the United States and partnerships in Africa, Australia, Mexico and Ukraine. RDO contacted ECSI for assistance in developing an Occupational Health and Safety Management System to help improve its OHS performance.

RDO also wanted to show its business partners, customers and employees, their commitment to keeping employees safe. RDO chose to align the OHS management system with ISO 45001. They also decided to initially seek certification from an accredited certification body for their corporate headquarters and one of the company stores. Their intention is to certify the remaining 42 stores over the year or so. ECSI conducted an initial gap assessment that helped RDO identify gaps that needed to be filled before getting certified.

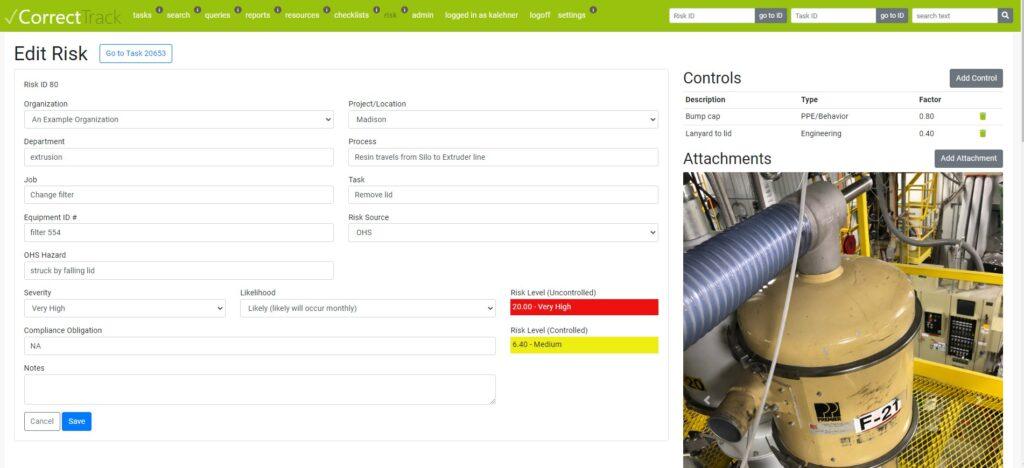

Gaps were entered into a database application tool (CorrectTrack) and assigned to the OHSMS implementation team for follow-up. One of the gaps identified was the need for a comprehensive Job Hazard/Job Safety analysis. ECSI helped develop process maps that supported JHA/JSA development at one of the RDO maintenance facilities. Below is an example of how the results of the JHA/JSA risk analysis were recorded.

This tool helped RDO evaluate the effectiveness of existing risk controls and identify priority hazards for additional risk reduction. The tool also helped internal auditors identify what material risks need to be audited during the internal audit process.

ECSI also helped RDO train its internal auditors in performing audits to the ISO 45001 standard. This was done in a three day combined internal audit training and actual audit at the corporate headquarters and one of the RDO maintenance facilities. ECSI assisted RDO in preparing for several management review meetings that were conducted prior to the Stage 1 and Stage 2 audits by an accredited certification body. Congratulations RDO on a successful outcome to the ISO 45001 implementation and certification process.